New York, 1879-1908

THE "GREAT SUCCESS." -- from The Publishers' Weekly, No. 511 (October 29, 1881), p543.

Mr. John B. Alden, the affable manager of the "Literary Revolution," has taken rather kindly to the remarks concerning the practical collapse of the "Revolution" made in the PUBLISHERS' WEEKLY," the commonly acredited organ (or, as some might say, considering its size and tone, ' Jewsharp') of the publishers and booksellers of the United States." In his usual cheerful way of looking at things he makes capital of the very debris. He answers with figures. He always answers facts with figures as readily as the grammar school-boy puts down the "millions" on his slate, and as promptly is ready for any sort of an explanation. Referring to the "stand-still," he pl ausibly calls it a "temporary withdrawal" and in the same facetious manner announces:

"As soon as we can overtake this demand (of which there is no probability for many months to come), we shall resume the publication of our miscellaneous books, when it is our purpose to make them generally of quality superior to our average in the past, and, consequently, at higher prices. Therefore, if you wish to secure any of our miscellaneous books at the extremely low prices heretofore given, you will have to buy them at the coming auction-sale in November."

The italics are our own. One of the big blasts of the Revolution was "you want no books more beautiful than ours "

The Bookseller and Stationer ("that Chicago fellow" and "good friend'), commenting on the same remarks turned to so good account by the clever "manager," takes this view of the matter:

"In explanation of .the above it may be said that the American Book Exchange has achieved a "second revolution," which its manager claims to be a more wonderful success than his first, and we are inclined for once to agree with him. He has advertised to close out his entire stock of miscellaneous books at a discount of thirty-three per cent from previous prices, and what is left of them will be dumped into a New York auction house early in November. Thereafter the Exchange will discontinue all its miscellaneous publications, notwithstanding the enormous profits they have been unceasingly. bringing into its treasury, according to its gifted manager's assertion, and devote its attention to the publication of an Encyclopedia."

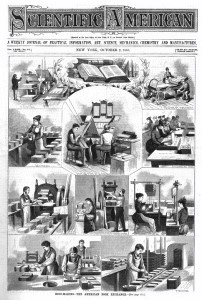

AMERICAN INDUSTRIES.--No. 56. BOOK-MAKING--THE AMERICAN BOOK EXCHANGE.

Scientific American XLIII:14 (2 October 1880), pages 211-212

Most people have heard the story, in one way or another, of the old lady who dropped into a bookstore one morning to have her old Bible reprinted, as she was advancing in years and wanted to get one in which the type was larger; how the obliging clerk took her order, and in the afternoon of the same day furnished her with a book having just the size of print and description of binding she required, and with which she was delighted as a faithful reproduction of her cherished volume. Probably there are not many at this day who believe that books are made de novo with such expedition; but the business of modern publishing houses requires the help of so many essentially different industries, and the division of labor is so carried into a hundred details, that comparatively few, except those who have made a speciality thereof have any adequate idea of the several processes and the number of different hands which the work goes through in making a printed book. We have, therefore, taken as the subject of our industrial sketch this week the leading departments of this business, as carried on by the “American Book Exchange,” the style of a company which has, within less than two years, become one of the largest publishers in the United States.

The business was inaugurated by the publication of one volume in January, 1879. It was started on the idea that the demand for standard books would be practically almost unlimited, if their price could be so reduced as to bring them within the reach of the masses. To be able to make large reductions in the price, it was imperative that extraordinary editions should be printed, as well as that their manufacture should be conducted according to the strictest business principles. Of a great proportion of the books printed such small editions are usually sold that the expense of the preparation of the plates, with even a moderate margin of profit to the publisher, makes the proportionate cost of each volume very high as compared with what it would he were the books sold by the hundred thousand. Starting with these facts, and with the determination to issue only such books as would be universally acknowledged as standard, the originators of this enterprise have already achieved a success so decided that, in looking over the work they are now doing, it seems no exaggeration when they claim to have effected a “literary revolution," for, although the business has been so recently established, they are now actually printing and selling over 5,000 books a day, nearly all of them being works such as no [sic] well selected library would be without, and the selling price being from one-fourth to one-tenth only of what the same books could previously have been bought for.

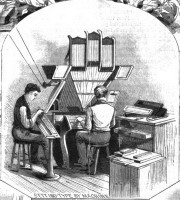

The initial work in the making of a book, after the “copy” is ready, is the composing or arranging of the types. This, in all books which do not contain elaborate engravings, or of which only small editions are printed, constitutes a main portion of the cost of manufacture. It is a branch of the business, however, in which it has been found very difficult to reduce the expense, as, notwithstanding all the effort made by inventors in different parts of the world for more than fifty years to perfect a machine for type-casting, it is only within a brief period that a successful working machine has been contrived, which, on plain work, will do the composition of a book at a lower price than the same can be done by hand. Such a machine, an illustration of which occupies the central position on the first page, has been at work in the “Gray:” printing office, in New York, for two years past, and a great deal of the composition required by the American Book Exchange has been done thereon. There are twenty of these machines in this establishment, and the cost of typesetting thereby is reduced nearly 50 per cent as compared with hand work. The machines are only suitable for plain work, such as history, biography, travels, etc., where but one kind of type is used throughout, and the text is free from italics, quotations from foreign languages, tables of figures, etc. The type is compactly held in three different metallic cases, with separate grooves for the supply of each letter, the letters all lying in the same position. These cases are at the top of the machine, and the operator sits in front of a keyboard just below; a touch on any one of the keys releases the particular letter or character desired, the bottom one in its special compartment of the case, when it drops by its own gravity into a channel that conducts it to its proper position in the matter being composed. The types are thus set up in one long line, which is steadily pushed out to the left of the operator, where a “justifier” with a measure cuts it off in lengths sufficient to make lines of the width of the page of a book or newspaper column, as may be desired.

The distribution of the type, or putting them back in regular order in the cases after the printing has been done or a plate made, is performed by a separate machine, which works automatically and very rapidly, needing only a boy to tend it. Each different letter or character has one or more nicks on the body of the type, so arranged as to be unlike the nicks on any other letter, and the distributing machine places each type in its proper place according to these nicks. An expert operator with one of these machines can compose from 45,000 to 55,000 ems of type in a day of ten hours, while good compositors will hardly average the composition and distribution of 7,000 ems each in the same time. Including the justification and distribution, the extra corrections which a machine calls for, and the occasional attention of a machinist, the cost of composition comes to something less than 20 cents per 1,000 ems.

There will always, however, be a great amount of work which, from the variety of characters employed, or the style of the text, must be done by hand, and the “Library of Universal Knowledge," now in course of publication, is of this description. It will be a verbatim reprint of the latest London edition of “Chambers’s Encyc1opedia,” with additions by American editors, covering some 15,000 separate topics, making one of the largest works of this class ever issued. It will make fifteen volumes, octavo, of nearly 1,000 pages each, closely printed type. Two volumes are to be issued monthly. S. W. Green's Son, a Beekman street printer, having contracted to do the composition of seventy pages a day regularly—an amount of work of this character which but few of our large printing offices would undertake to accomplish.

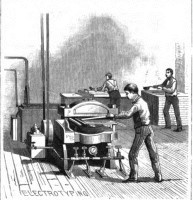

It is very rare that a book is now printed directly from the types, but a mould is taken from the type form, from which a plate is made to print from. An illustration on this page shows a large press in which the type form is placed to make this mould, the face of the type being carefully brushed with black lead, and the impression being made in wax, which is spread about a sixteenth of an inch thick on a metal backing. This wax mould is suspended in a solution of sulphate of copper, sulphuric [sic] acid, and water, and connection being made with an electric machine, the copper is deposited in the mould to represent the impression left in the type by the wax, the finest lines of the most delicate engraving clearly and sharply brought out. It takes about three hours time for the deposit of sufficient copper to make a plate which will wear well, and when this is accomplished type metal is cast upon the hack of the thin sheet of copper made to form a solid backing. The plates are now carefully planed down on their backs to a uniform regular thickness, trimmed on the edges, and, where the letterpress would show a good deal of white paper in printing, some of the extra metal is cut or “routed” out. The electrotyping for these publications is done at the establishment of Lovejoy & Son, who have for several years made the electrotype plates from which the SCIENTIFIC AMERICAN is printed.

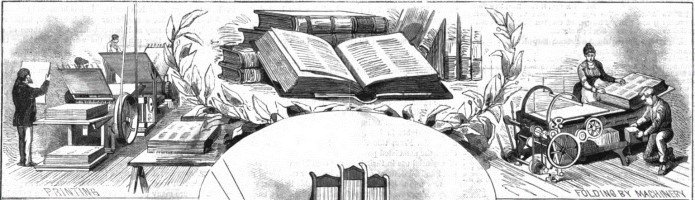

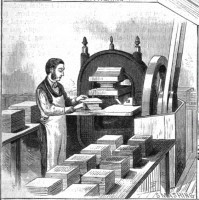

The types being set and the plates made, the form is now ready to “go to press,” as printers term it, and one of the illustrations at the top of the first page represents the printing process. The work of the Book Exchange has so quickly grown to such great dimensions that it has been difficult to engage a sufficient number of the kind of presses desired to do the work. The Adams press does the greater part of the printing, over fifty presses being kept constantly at work, and fifteen of these working through twenty-four hours a day. The Adams press is an old style book press, which does not work quite as rapidly as some presses of more recent design, but it has a thorough ink distribution, gives a firm, clear, and even impression, and has always been a favorite with printers for work which was to be done with great care. There are other presses which it is claimed will do as good printing, but it is not pretended that any of them will do better book work than the Adams press.

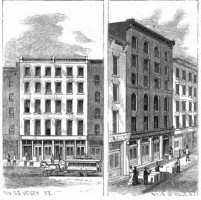

The sheets are now ready for binding, leading details of which are represented in the other illustrations on the first page. The printing is usually done in large forms, with 16, 24, 82, 36, or 48 pages on one side of a sheet, each sheet being styled a signature, and so marked at the bottom of the first page of such signature, that, when the binder places the signatures in consecutive order, the pages of the book will all come in their proper places. The binding is all done in establishments expressly fitted up for this purpose at 18 Spruce street, 26 Beekman street, 83 and 85 Vesey street, and 8 Church street, where also are the packing and shipping departments of the business. Representations of these several More than 5,000 books are now being bound daily in cloth and half Russia at these binderies, and new machinery is being put in, which, with the additional help that can be employed, is intended to double this capacity. The number of hands now engaged in this department averages 75 men and 140 women and girls.

The folding of some of the work is done by hand, while a large portion is done on folding machines, of which there are six in constant operation. The machine will fold the sheets about as fast as a feeder can supply them. The sheet is laid by points, so that the printed matter in each page will come in just the same relative position with that in all the other pages, when a long, light strip of metal, held by curved arms, comes down and forces it through a narrow opening in the table-like top of the machine, whence it is taken through a series of tapes and rollers arranged so as to give just the folds required.

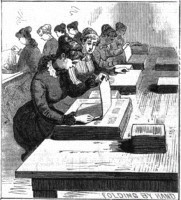

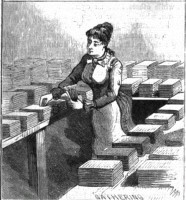

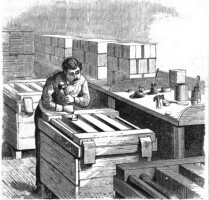

After the folding comes the “gathering," or the putting together of the different sheets which make a book. The manner in which this is done will be readily understood from the illustration, in which the employee is seen surrounded by piles of sheets, taking one from each pile successively until all the signatures of a book are held together in the hand.

As may be supposed, in the rapidity with which the folding and gathering are performed the sheets are not pressed firmly and solidly together as they appear in a bound book but to effect this they are put in a powerful press, called the “smasher,” which instantly squeezes them so tight that the book will then be almost as hard as a board, and only an outside leaf or so in a pile of several thousand will be loose. In this state they are taken to a machine where two or three or more shallow cuts are sawed across the backs, just sufficient to allow room for a strong cord to pass through.

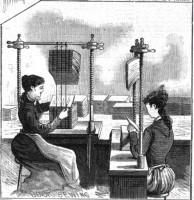

In the sewing, the books as gathered are placed in piles from 12 to 18 inches high, and these cords are arranged on frames at such distances that they will pass through the cuts sawed in the backs of the sheets. The cords are kept taut by screws in the frames, and each sheet is sewed around these cords, but so that the whole pile of books sewed around the cords may be worked along, to allow of little ends of cord being left on each side, when the string of books, as it might be called, is cut apart. These ends are made firm with glue in the cover or casing, when that is put on, and glue entirely over the back also holds the cords in their places. After the sewing the edges have to be trimmed in a cutter, of which there are several styles, then the back is rounded by a machine, the volume being held in a sort of vise, which will yet allow the signatures to be slightly moved, when a roller moving in a circle is passed forward and back over the back of the volume. The old style of doing this work was by pounding the edges with a mallet, but the machine has entirely superseded this class of work.

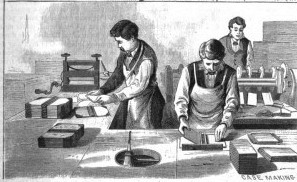

The dexterity with which experienced bands can put together book covers cannot fail to be surprising to one witnessing the operation for the first time. A particular kind of thin muslin, made for the purpose, and furnished in as many different shades as there are styles of dress prints in a season, is the staple article for all “cloth” bindings. It is cut enough larger than the two sides and back of a book to allow room to fold the edges well over, but the pasteboard it is intended to cover is cut out, generally by a machine, of the desired shape and size. A workman will lay out a dozen of these muslin pieces for covers, brush them thoroughly with glue, place the pasteboard for the sides in position, put in a piece of thick paper or cardboard to stiffen the back, deftly fold over all the edges, and pass the whole pile through a press, almost before an observer comprehends what he is doing.

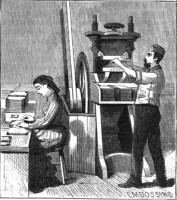

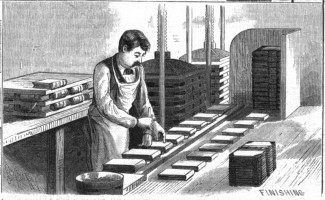

When the edges of a book are to be gilded this part of the work is done after the trimming, a great number of books being held tightly in a press, when the edges, which are trimmed so evenly and held so closely that they present a smooth surface, are brushed over with a thin sizing, made principally of isinglass glue, and the gold leaf is laid on and burnished with a hot iron. The stamping, or lettering on the covers in gold, is done very much after the same principle, the gold leaf being pressed in by a heated stamp. The embossing, by which the various designs of cloth covers are made, either plain or with ink impressed in the design, is done in a powerful press, especially built for this purpose, from metal patterns cut in a great variety of styles. After this the book is ready for the finisher, who puts on its case or cover, making the inside of the cover to match the fly leaf at the front and back, putting in a beaded or corded trimming around the back at top and bottom if desired, and remedying any imperfections which may have been allowed to pass in other portions of the work.

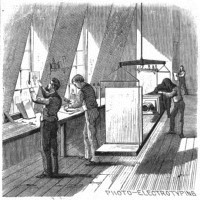

We have thus followed the book through, from the time the copy is put in the printer's hands until the volumes are ready to go to the shelves of the bookseller, but our notice would be incomplete without reference to the work done by what is called the “process” system of engraving. There are several patented methods of doing this work, and it is a distinct branch of business which has grown up entirely within the past fifteen years. By these processes a photograph is made of what is to be reproduced, from either a woodcut, a steel or copper engraving, a lithograph, a pen and ink drawing, or a page of printed matter. In this manner the publishers are now reproducing by photo-electrotypes the plates of Young‘s “Bible Concordance," a very elaborate work, in which, interspersed through the English text, are numerous quotations from the Greek, Hebrew, and Arabic, making a book which would prove a very difficult work for the most skillful compositor or the most accomplished proof-reader. In this way, however, the pages are simply put before a camera, when a negative is taken by which an exact impression is made through a thin film of wax, when all the other parts are eaten away by acids, leaving the clear representation of the picture or print photographed in relief with an accuracy which can only be secured by such process. From this wax mould electrotypes are made in the same way as from a type form.

A great proportion of the books first issued by the American Book Exchange were such as have long been the common property of mankind, irrespective of any author’s copyright property, such as the works of Macaulay, Gibbon, Milton, Goldsmith, the ancient classics, etc., besides others, which, in the absence of any copyright treaties with other countries, all American publishers are at liberty to reprint. On several of their works, however, they pay a copyright to authors, and, from the great number of copies sold of every work they take up, a small percentage on each not only makes the author’s remuneration considerable, but affords him the further gratification, of infinitely greater worth to most authors, of knowing that his efforts are appreciated by the reading public. Beyond this, however, the publishers have a special editorial corps of their own, including the names of authors who have for years enjoyed a high literary reputation, and their expenses in this department alone now amount to about $20,000 a year.

No more statement, however, covering the details of this extended industry can give a correct comprehension of the value of the work to the general public which is thus being accomplished. A library of the best description is, by this system of publishing, made to cost so little that there are but few mechanics and laboring men in the country who cannot, if they will, become the possessors of the works of some of the greatest authors who ever lived. As a factor in the education of the rising generation its influence will be widely felt, for, of the 5,000 standard books a day now being sold at these low prices, it is safe to say that only a very small proportion would be taken at the prices which such works have heretofore cost. They now go to the masses, to people who buy because they want to read them, and not to use them to fill up so many square feet of wall space in a library, and the rapidity with which the demand is increasing affords the best possible evidence that the American Book Exchange is meeting an acknowledged want of the reading community.

The details of the business in every department are under the personal management of Mr. John B. Alden, Manager, in the Tribune Building, where the offices and a large retail store are situated.

Last revised: 11 July 2020