CHAPTER XXIV

Economics in Design for Erection Considerations

|

The tyro in bridge designing, no matter how profound may be his theoretical knowledge, often falls down very hard until he has learned through sad experience that the erectors of structural steelwork have certain standard requirements which must be observed. If they be ignored, the work is often seriously delayed; and, as delays in the field are exceedingly expensive, the matter of making the designs so that all the metal will go together easily and expeditiously involves engineering economics of great importance. The failure to furnish sufficient clearance is generally the tyro's first offense—and it certainly is a serious one. If the designer who commits this blunder could hear what the bridge erectors say about him, his ears would certainly tingle. Mr. Wolfel's general instructions concerning designing to meet field requirements are as follows:

(1) Allow ample clearance for all entering connections.

(2) Provide erection shelves for girders and beams, particularly when they frame opposite each other.

(3) Have all riveting arranged in such a way that it can follow the erection of the work. Riveting should never be allowed to interfere with the raising and placing of the steel.

(4) Be sure that cross frames in deck bridges can be swung in place without spreading the girders.

(5) Be careful in through plate-girders to arrange the stiffeners so that the floor-beams and stringers can be put in place with the girders in their final position.

(6) Arrange the riveting around the ends of the spans so that the rivets can be |

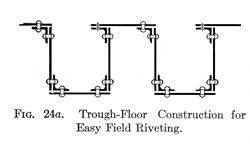

| driven with the steel in the final position. It should never be necessary to jack up spans to drive rivets. (7) In trough floorwork, especially where the under clearance is small, arrange the design so that all field rivets can be driven from the top, as in Fig. 24a. (8) While it has been customary to call for 25 per cent excess for all field rivets, 10 per cent excess should be suffient if the riv- |

|

ets are driven with air hammers.

On this subject Mr. Reichmann has written thus:

The designer should always remember to allow plenty of clearance at the ends of sheared members so as to take up variations of shopwork. One-half inch clearance is considered a minimum for sheared ends. For entering connections, plenty of clearance

214 |